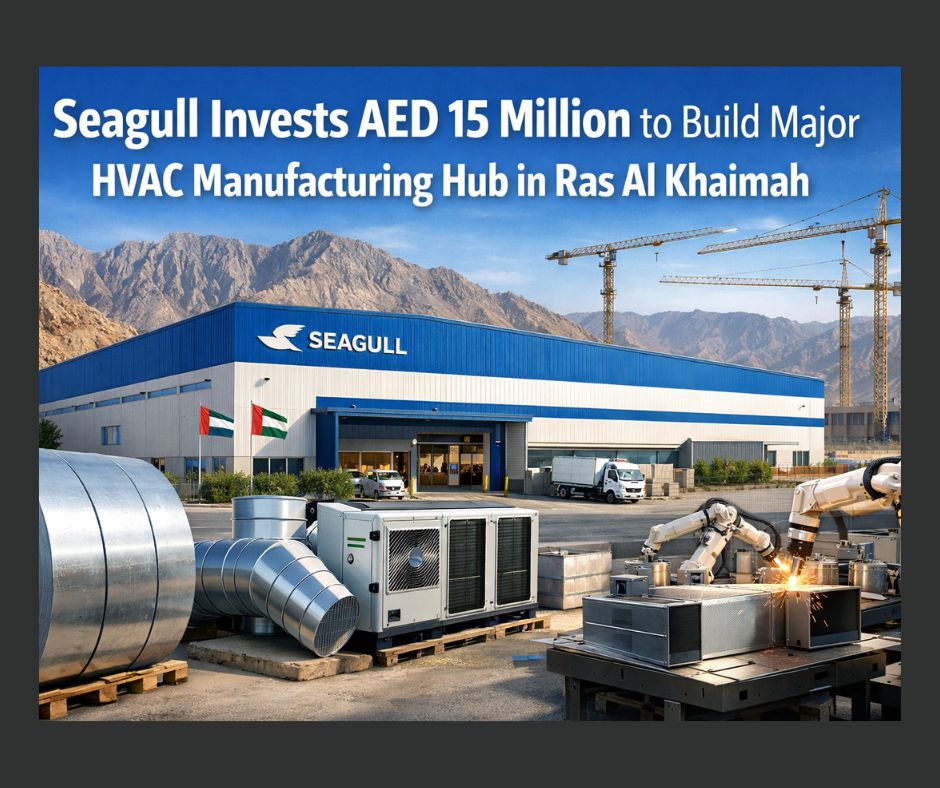

In a region where temperature control isn’t a luxury but a lifeline, the homegrown UAE firm Seagull has just signaled its intent to dominate the Gulf’s climate control market. With a fresh AED 15 million ($4.08 million) investment, the HVAC (Heating, Ventilation, and Air Conditioning) pioneer has inaugurated a 17,045 m² manufacturing facility in the Al Ghail Industrial Zone of Ras Al Khaimah.

This expansion is more than just a capacity hike; it is a tactical relocation into the Ras Al Khaimah Economic Zone (RAKEZ), positioning Seagull to feed the massive construction booms currently sweeping through Saudi Arabia, Oman, and Qatar.

The “50,000 m²” Engine: Understanding the Output

The facility’s headline capability—a monthly production of 50,000 m² of Galvanized Iron (GI) coils—is the backbone of modern HVAC systems. For perspective:

- What it means: These coils are fabricated into the air ducting systems found in skyscrapers, airports, and malls.

- The Scale: 50,000 m² is roughly equivalent to producing enough ductwork to line seven FIFA-standard football pitches every single month.

- The Regional Play: By manufacturing these bulky components in the cost-effective environment of RAKEZ, Seagull can ship faster and cheaper to the GCC’s major project sites, directly challenging global imports.

Analysis: Why Ras Al Khaimah is the Strategic Pick

The decision by Taimor Khan (CFO) and the Seagull leadership to choose RAKEZ over other industrial hubs boils down to industrial synergy and logistics:

- Cost-to-Growth Ratio: Ras Al Khaimah offers one of the most competitive industrial setups in the UAE. For a company dealing with heavy raw materials like GI coils, lower overheads in Al Ghail translate into better pricing for contractors.

- The Construction Catalyst: Ramy Jallad (CEO of RAKEZ) noted the growing confidence in the emirate’s ecosystem. With UAE construction activity accounting for 44% of all MENA projects, being located in a hub that supports everything from licensing to visa processing allows Seagull to focus entirely on production.

- Labor & Wellbeing: Unusually for a heavy industrial facility, Seagull is prioritizing a “world-class manufacturing workplace.” This includes integrated staff accommodation—a move designed to retain the 180-strong workforce as they scale toward 300 employees by mid-2026.

The Roadmap: Doubling Down by 2026

Seagull isn’t stopping at the current ribbon-cutting. The company’s trajectory for the next 18 months is aggressive:

- Capacity Expansion: Plans are already in place to double the factory floor space by 2026.

- Product Diversification: Beyond ductwork, the expanded space will house new lines for fire-rated ducting and acoustic products, catering to the strict safety codes of Saudi’s “Giga-projects” like NEOM and The Red Sea.

- Headcount Growth: An additional 120 skilled roles are expected to be created, supporting the UAE’s broader “Operation 300bn” goal to increase the industrial sector’s contribution to the GDP.

Quick View: Seagull’s RAKEZ Footprint

| Feature | Details |

| Total Investment | AED 15 Million |

| Facility Size | 17,045 m² |

| Current Workforce | 180 (Targeting 300 by 2026) |

| Core Product | GI Coils for HVAC Ducting |

| Target Markets | UAE, KSA, Oman, Qatar |

Shriram Pistons Buys Manufacturing Muscle for ₹28 Crore in Precision Capacity Play.